Geopolymerization presents an environmentally friendly and sustainable alternative to conventional construction materials, particularly in the production of compressed stabilized earth bricks (CSEB). This study investigates the influence of two key production factors which are the volcanic ash/laterite mass ratio (X1) and the amount of phosphoric acid (H₃PO₄) activating solution (X2), on the physicochemical and mechanical properties of CSEB. The raw materials, laterite and volcanic ash collected from the Adamaoua region in Cameroon, exhibit low porosity, high specific surface area, and are rich in silica and alumina oxides. The central composite design (CCD) was employed to model and optimize the CSEB production process, with compressive strength as the response variable. Results indicate that the compressive strength is predominantly governed by the mass ratio of volcanic ash to laterite, whose main effect is 49 times greater than that of the H₃PO₄ amount. However, due to the significant interaction effect between the volcanic ash/laterite mass ratio and the amount of H₃PO₄, and the important quadratic effect of the volcanic ash/laterite mass ratio, the variation in compressive strength is nonlinear. Optimal conditions were determined to be a volcanic ash/laterite mass ratio of 0.16 and an H₃PO₄ amount of 8.69 mL, yielding a compressive strength of 33MPa. The evaluation of the hydration behavior of CSEB under optimal conditions revealed minimal water absorption under capillary rise and full immersion. In the wet state, the compressive strength decreased by approximately 10% (full immersion) and 8% (partial immersion) compared to the dry state. Overall, geopolymerization significantly enhances both the compressive strength and water resistance of CSEB.

| Published in | American Journal of Construction and Building Materials (Volume 9, Issue 1) |

| DOI | 10.11648/j.ajcbm.20250901.12 |

| Page(s) | 12-21 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Compressed Stabilized Earth Bricks, Geopolymerization, Laterite, Volcanic Ash, Production Factors, Central Composite Design, Compressive Strength

Factors | Levels of variation | ||||

|---|---|---|---|---|---|

-α | -1 | 0 | +1 | +α | |

X1 | 0.05 | 0.08 | 0.17 | 0.25 | 0.28 |

X2 | 1.96 | 3.00 | 5.50 | 8.00 | 9.03 |

(1)

(1) Laterite | Volcanic ash | |

|---|---|---|

Absolut density (g/cm3) | 2.05 | 2.01 |

Apparent density (g/cm3) | 1.18 | 0.98 |

Water content (%) | 7.33 | 8.00 |

Apparent porosity (%) | 4.18 | 7.52 |

Specific area (m2/g) | 79.37 | 121.39 |

Oxides (%) | Laterite | Volcanic ash |

|---|---|---|

SiO2 | 31.26 | 46.18 |

Al2O3 | 20.89 | 17.03 |

Fe2O3 | 36.83 | 12.56 |

TiO2 | 3.32 | 2.81 |

MnO2 | 0.04 | 0.19 |

MgO | 0.29 | 6.40 |

CaO | 0.03 | 6.94 |

Na2O | < 0.004 | 3.42 |

K2O | 0.22 | 1.25 |

SrO | / | 0.13 |

SO3 | 0.04 | / |

Cr2O3 | / | / |

BaO | / | 0.08 |

P2O5 | 0.06 | 0.61 |

ZrO2 | 0.13 | / |

LOI | 6.87 | 0.63 |

Total | 99.98 | 99.92 |

SiO2 /Al2O3 | 1.50 | 2.71 |

N°exp | Experimental Conditions | CSExp (Mpa) | |

|---|---|---|---|

X1 (%) | X2 (ml) | ||

1 | 0.08 | 3.00 | 14.00 |

2 | 0.25 | 3.00 | 10.00 |

3 | 0.08 | 8.00 | 22.00 |

4 | 0.25 | 8.00 | 22.00 |

5 | 0.05 | 5.50 | 10.00 |

6 | 0.28 | 5.50 | 2.00 |

7 | 0.17 | 2.00 | 22.00 |

8 | 0.17 | 9.00 | 33.00 |

9 | 0.17 | 5.50 | 20.00 |

10 | 0.17 | 5.50 | 21.00 |

11 | 0.17 | 5.50 | 19.00 |

12 | 0.17 | 5.50 | 21.00 |

13 | 0.17 | 5.50 | 20.00 |

Values | Validation conditions | |

|---|---|---|

R² | 0.98 | > 90% |

AAMD | 0.01 | 0 ≤ AAMD ≤ 0.3 |

Bf | 1.01 | 0.75 ≤ Bf≤ 1.25 |

Af1 | 1.01 | 0.75 ≤ Af1≤ 1.25 |

Af2 | 1.05 | 0.75 ≤ Af2≤ 1.25 |

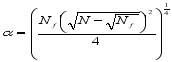

Coefficients values | |

|---|---|

X1 | 273 |

X2 | 5.53 |

X1X2 | 4.71 |

X12 | 974 |

X22 | 0.59 |

Constant | 9.86 |

CSEB | Compressed and Stabilized Earth Brick |

MPa | Mega Pascal |

CS | Compressive Strength |

CSExp | Experimental Compressive Strength |

CRAterre | Earthen Research and Application Center |

| [1] | Mohamed B. M., Ahmed J. A., Soukaina C. & Sadok B. J. Optimizing thermal and mechanical performance of compressed earth blocks (CEB). Construction and Building Materials. 2016. 104. 44-51. |

| [2] | Sore S. O., Messan A., Prud’homme E., Escadeillas G. & Tsobnang F. Synthesis and characterization of geopolymer binders based on local materials from Burkina Faso – Metakaolin and rice husk ash. Construction and Building Materials. 2016. 124. 301 311. |

| [3] | Mimboe A. G., Abo M. T., Djobo J. N. Y., Tome S., Kaze R. C. & Deutou J. G. N., Lateritic soil based-compressed earth bricks stabilized with phosphate binder. Journal of Building Engineering. 2020. 31. 101465. |

| [4] | Preethi R. K. & Venkatarama Reddy B. V. Characteristics of geopolymer stabilised compressed earth bricks. Structures. 2024. 61. 106007. |

| [5] | Djobo J. N. Y. & Tome S. Insights into alkali and acid-activated volcanic ash-based materials: A review. Cement and Concrete Composites. 2024. 152. 105660. |

| [6] | Mendes B. C., Pedroti L. G., Vieira C. M. F., Marvila M., Azevedo A. R. G., Franco de Carvalho J. M. & Ribeiro J. C. l. Application of Eco-Friendly Alternative Activators in Alkali-Activated Materials: A Review. Elsevier Ltd. Journal of Building Engineering. 2021. 102-010. |

| [7] | Tchouateu K. R. A., Tchadjie N. L., Tome S., Eguekeng I., Nemaleu D. G. J., Tommes B., Woschko D., Janiak C. & Etoh M. A. A comparative study of compressed lateritic earth bricks stabilized with natural pozzolan-based geopolymer binders synthesized in acidic and alkaline conditions. Construction and Building Materials. 2023. 400. 132652. |

| [8] | Fatheali A., Shilar S. V., Ganachari V. B., Patil N. A. & Yunus K. Development and optimization of an eco-friendly geopolymer brick production process for sustainable masonry construction. Case studied in construction materials. 2023. 18. e02133. |

| [9] | Dipankar D., Gołąbiewska A. & Prasanta K. R. Geopolymer bricks: The next generation of construction materials for sustainable environment. Construction and Building Materials. 2024. 445. 137876. |

| [10] | Tiffo E., Bike Mbah J. B., Belibi Belibi P. D., Djobo J. N., & Elimbi A. Physical and mechanical properties of unheated and heater kaolin based-geopolymees with partial replacement of aluminum hydroxide. Materials Chemicals and physics. 2020. 239. 122-103. |

| [11] | Mouhamadou A., Bhargav L., Ali A., Mahfoud B., & Nor-Edine A. Geopolymer synthesis and performance paving the way for greener building material: A comprehensive study. Case studied in construction materials. 2024. 20. e03280. |

| [12] | Nshimiyimana P., Fagel N., Messan A.; Wetshondo D. O., & Courard L. Physico-chemical and mineralogical characterization of clay materials suitable for production of stabilized compressed earth blocks. Construction and Building Materials. 2020. 241. 118-097. |

| [13] | Coelho T. P. P., Bezerra B. P., Verza J. R., Luz A. P., & Morelli M. R. Physico-mechanical properties of metakaolin and diatomite-based geopolymers. Materials Letters. 2023. 349. 134784. |

| [14] | Kaze C. R., Lecomte-Nana G. L., Kamseu E., Camacho P. S., Yorkshire A. S., Provis J. L., Duttine M., Wattiaux A., & Melo U. C. Mechanical and physical properties of inorganic polymer cement made of iron-rich laterite and lateritic clay: a comparative study. Cement Concr. Res. 2021. 140. 106320. |

| [15] | Tchouateu K. R. A., Tome S., Chongouang J., Eguekeng I., AlSpieß A., Fetzer M. N. A., Kamseu E., Janiak C. & Etoh M. A Stabilization of compressed earth blocks (CEB) by pozzolana based phosphate geopolymer binder: Physico-mechanical and microstructural investigations. Cleaner Materials. 2022. 4. 100062. |

| [16] | Sontia M. J. V., Kaze C. R., Deutou J. G., Venyite P., Nana A., Kamseu E., Melo U. C. & Tatietse T. T. Evaluation of performances of volcanic-ash-laterite based blended geopolymer concretes: mechanical properties and durability. Journal of Building Engineering. 2021. 34. 101935. |

| [17] | Pougnong T. E., Belibi P. D., Baenla J., Thamer A., Tiffo E., & Elimbi A. Effects of chemical composition of amorphous phase on the reactivity of phosphoric acid activation of volcanic ashes. Journal oh Non-Crystalline Solids. 2022. 575. 121-213. |

| [18] | Chaibeddra S. & Kharchi F. Performance of Compressed Stabilized Earth Blocks in sulphated medium. Journal of Building Engineering. 2019. 25. 100-814. |

| [19] | Zhang Z., Wong Y. C., Arulrajah A. & Horpibulsuk S. A review of studies on bricks using alternative materials and approaches. Construction and Building Materials. 2018. 188. 1101–1118. |

| [20] | Preethi R. K. & Venkatarama R. B. Experimental investigations on geopolymer stabilised compressed earth products. Construction and Building Materials. 2020. 257. 119-563. |

| [21] | Sore O. S., Messan A., Prud’homme E., Escadeillas G. & Tsobnang F. Stabilization of compressed earth blocks (CEBs) by geopolymer binder based on local materials from Burkina Faso. Construction and Building Materials. 2018. 165. 333–345. |

| [22] | Ruiz G., Zhang X., Edris W. F., Cañas I. & Garijo L. A comprehensive study of mechanical properties of compressed earth blocks. Construction and Building Materials. 2018. 176. 566-572. |

| [23] | Djon Li Ndjock B. I., Baenla J., Bike Mbah J. B. & Elimbi A. Amorphous phase of volcanic ash and microstructure of cement product obtained from phosphoric acid activation. SN Applied Sciences. 2020. 2: 720. |

| [24] | Hongbo W., Mingsheng H., Shenghong W., Jianjun C., Tao W., Yali C., Yongkun D., & Qiuye D. Effects of binder component and curing regime on compressive strength. capillary water absorption. shrinkage and pore structure of geopolymer mortars. Construction and Building Materials. 2024. 442. 137707. |

| [25] | Fadele O. A. & Ata. O. Water absorption properties of sawdust lignin stabilised compressed laterite brick. Case Studies in Construction Materials. 2018. |

| [26] | Udawattha C., De Silva D. E., Galkanda H. & Halwatura R. Performance of natural polymers for Stabilizing earth blocks. Materialia. 2018. |

| [27] | Lawane A., Minane J. R., Vinai R. & Pantet A. Mechanical and physical properties of stabilised compressed coal bottom ash blocks with inclusion of lateritic soils in Niger. Scientific African. 2019. e00198. |

| [28] | Fouchal F., Gouny F., Maillard P., Ulmet L. & Rossignol S. Experimental evaluation of hydric performances of masonry walls made of earth bricks. geopolymer and wooden frame. Building and Environment. 2015. 87. 234–243. |

| [29] | Nobouassia B. C., Tchakoute H. K., Fotio D., Rüscher C. H., Kamseu E. & Leonelli C. Water resistance and thermal behavior of metakaolin-phosphatebased geopolymer cements. J. Asian Ceram. Soc. 2018. 6. 271–283. |

APA Style

Canuala, T. T. L., Ngaba, T., Baptiste, B. M. J., Tout, A. J. C. J. C. D., Honoré, F. (2025). Effects of Production Factors on the Physicochemical and Mechanical Properties of Compressed Earth Bricks Stabilized by Geopolymerization. American Journal of Construction and Building Materials, 9(1), 12-21. https://doi.org/10.11648/j.ajcbm.20250901.12

ACS Style

Canuala, T. T. L.; Ngaba, T.; Baptiste, B. M. J.; Tout, A. J. C. J. C. D.; Honoré, F. Effects of Production Factors on the Physicochemical and Mechanical Properties of Compressed Earth Bricks Stabilized by Geopolymerization. Am. J. Constr. Build. Mater. 2025, 9(1), 12-21. doi: 10.11648/j.ajcbm.20250901.12

@article{10.11648/j.ajcbm.20250901.12,

author = {Tekoumbo Tedontsa Larissa Canuala and Taybe Ngaba and Bike Mbah Jean Baptiste and Adatz Jean Claude Jean Claude De Tout and Fognaba Honoré},

title = {Effects of Production Factors on the Physicochemical and Mechanical Properties of Compressed Earth Bricks Stabilized by Geopolymerization

},

journal = {American Journal of Construction and Building Materials},

volume = {9},

number = {1},

pages = {12-21},

doi = {10.11648/j.ajcbm.20250901.12},

url = {https://doi.org/10.11648/j.ajcbm.20250901.12},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.ajcbm.20250901.12},

abstract = {Geopolymerization presents an environmentally friendly and sustainable alternative to conventional construction materials, particularly in the production of compressed stabilized earth bricks (CSEB). This study investigates the influence of two key production factors which are the volcanic ash/laterite mass ratio (X1) and the amount of phosphoric acid (H₃PO₄) activating solution (X2), on the physicochemical and mechanical properties of CSEB. The raw materials, laterite and volcanic ash collected from the Adamaoua region in Cameroon, exhibit low porosity, high specific surface area, and are rich in silica and alumina oxides. The central composite design (CCD) was employed to model and optimize the CSEB production process, with compressive strength as the response variable. Results indicate that the compressive strength is predominantly governed by the mass ratio of volcanic ash to laterite, whose main effect is 49 times greater than that of the H₃PO₄ amount. However, due to the significant interaction effect between the volcanic ash/laterite mass ratio and the amount of H₃PO₄, and the important quadratic effect of the volcanic ash/laterite mass ratio, the variation in compressive strength is nonlinear. Optimal conditions were determined to be a volcanic ash/laterite mass ratio of 0.16 and an H₃PO₄ amount of 8.69 mL, yielding a compressive strength of 33MPa. The evaluation of the hydration behavior of CSEB under optimal conditions revealed minimal water absorption under capillary rise and full immersion. In the wet state, the compressive strength decreased by approximately 10% (full immersion) and 8% (partial immersion) compared to the dry state. Overall, geopolymerization significantly enhances both the compressive strength and water resistance of CSEB.

},

year = {2025}

}

TY - JOUR T1 - Effects of Production Factors on the Physicochemical and Mechanical Properties of Compressed Earth Bricks Stabilized by Geopolymerization AU - Tekoumbo Tedontsa Larissa Canuala AU - Taybe Ngaba AU - Bike Mbah Jean Baptiste AU - Adatz Jean Claude Jean Claude De Tout AU - Fognaba Honoré Y1 - 2025/06/30 PY - 2025 N1 - https://doi.org/10.11648/j.ajcbm.20250901.12 DO - 10.11648/j.ajcbm.20250901.12 T2 - American Journal of Construction and Building Materials JF - American Journal of Construction and Building Materials JO - American Journal of Construction and Building Materials SP - 12 EP - 21 PB - Science Publishing Group SN - 2640-0057 UR - https://doi.org/10.11648/j.ajcbm.20250901.12 AB - Geopolymerization presents an environmentally friendly and sustainable alternative to conventional construction materials, particularly in the production of compressed stabilized earth bricks (CSEB). This study investigates the influence of two key production factors which are the volcanic ash/laterite mass ratio (X1) and the amount of phosphoric acid (H₃PO₄) activating solution (X2), on the physicochemical and mechanical properties of CSEB. The raw materials, laterite and volcanic ash collected from the Adamaoua region in Cameroon, exhibit low porosity, high specific surface area, and are rich in silica and alumina oxides. The central composite design (CCD) was employed to model and optimize the CSEB production process, with compressive strength as the response variable. Results indicate that the compressive strength is predominantly governed by the mass ratio of volcanic ash to laterite, whose main effect is 49 times greater than that of the H₃PO₄ amount. However, due to the significant interaction effect between the volcanic ash/laterite mass ratio and the amount of H₃PO₄, and the important quadratic effect of the volcanic ash/laterite mass ratio, the variation in compressive strength is nonlinear. Optimal conditions were determined to be a volcanic ash/laterite mass ratio of 0.16 and an H₃PO₄ amount of 8.69 mL, yielding a compressive strength of 33MPa. The evaluation of the hydration behavior of CSEB under optimal conditions revealed minimal water absorption under capillary rise and full immersion. In the wet state, the compressive strength decreased by approximately 10% (full immersion) and 8% (partial immersion) compared to the dry state. Overall, geopolymerization significantly enhances both the compressive strength and water resistance of CSEB. VL - 9 IS - 1 ER -